Thermal transfer technology uses high temperature and high pressure to directly penetrate and solidify the digital pattern on the glass surface, achieving permanent fusion of the image and the cup body.

Submit feedback

-

0120+ Industry Experience

With over 20 years of experience in the thermal transfer printing industry, we have accumulated a rich database of process technologies and extensive application experience. From apparel printing to building materials films, our deep understanding of color in various fields ensures the efficient implementation of client projects.

-

02Strong R&D Team

Our R&D team, led by experts in materials science and mechanical automation, continuously invests in the development of new materials and processes. We have successfully developed several patented environmentally friendly water-based formulations and high-efficiency transfer technologies, providing your products with a unique competitive advantage in the market.

-

03Customer Support and ODM Experience

We offer full-process ODM services from design and proofing to mass production. We specialize in providing personalized pattern design, material selection, and process optimization solutions based on your brand positioning and cost budget, helping you quickly launch differentiated products.

-

04Full-cycle Customer Service

We provide a "technical advisory" service throughout the entire project. From initial solution consultation, mid-term proofing and debugging, to post-production follow-up, our dedicated team provides 24-hour rapid response and technical support to ensure your project is worry-free throughout.

-

01Daily Necessities

01Daily Necessities -

02Toys

02ToysThermal transfer technology seamlessly transforms flat designs into tangible three-dimensional reality, giving toys a more vivid soul and more lasting charm. It is an indispensable exquisite "makeup technique" in modern toy manufacturing.

-

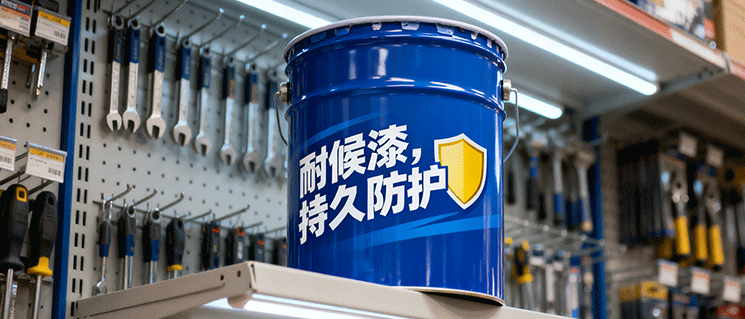

03Decoration Material Packaging

03Decoration Material PackagingBy giving the packaging excellent durability and advanced visual expression, it not only protects the product during logistics and use, but also becomes a powerful and lasting communication medium in sales and brand building, effectively supporting the brand's high-end positioning.

-

04Furniture

04FurnitureIt can highly simulate the texture of natural wood, stone and even textiles, with rich color layers and realistic touch, meeting the market demand for natural aesthetics and personalized design.

brand value-added

In a highly competitive market, the visual appeal of a product is the key to success. We understand that a perfect pattern is more than just a print; it conveys the soul of a brand.

-

01

Process-Oriented Quality Management

Process-Oriented Quality Management

We have established a closed-loop quality management system that covers design review, pre-production proofing, process control, and final shipment inspection.

-

02

High-Quality Materials and Workmanship

High-Quality Materials and Workmanship

We strictly select environmentally friendly, high adhesion transfer films and premium inks to ensure vivid, long lasting designs.

-

03

Comprehensive Inspection Process

Comprehensive Inspection Process

We enforce a multi stage inspection procedure to rigorously screen out non conforming products before shipment, guaranteeing that every delivered item meets the required standards.

English

English عربى

عربى 中文简体

中文简体 Español

Español